The Challenge

A major Middle East operator, with long string cemented high-production 10,000psi gas wells, required an improved solution to efficiently workover wells with tubing and casing integrity issues. The existing methods being employed involved a complex array of equipment that did not provide pressure integrity between the tubing stump and new upper completion, resulting in the casing and top of cement being exposed to production.

The customer ultimately wanted to remediate the wells and re-establish the tubing connection with mechanical and pressure integrity with a solution that was V0-rated in line with their well barrier policy. Simplifying the operations and reducing time and cost was a secondary driver for an improved solution.

The Viking Solution

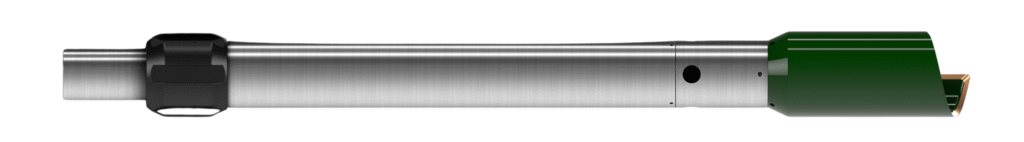

Viking’s existing Well Remediation system was re-configured and validated to provide a 10,000 psi API 19AC V0-rated connection to the tubing stump after cutting. A Viking Washover Assembly was designed in parallel to prepare the cut tubing stump for the high-pressure, proprietary gas-tight seals and integral tubing anchor.

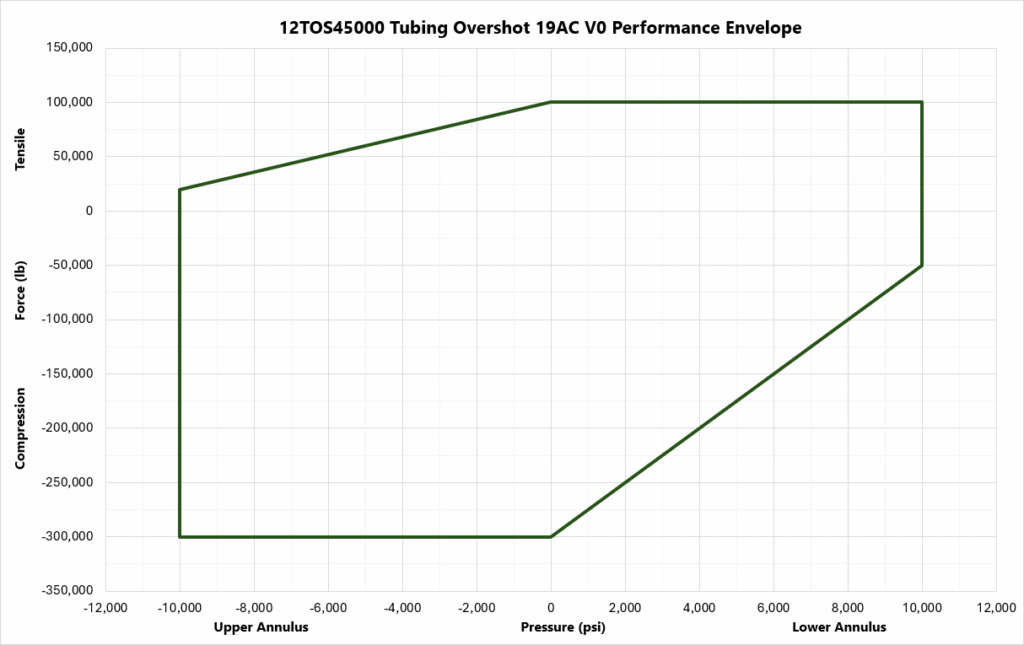

The system underwent rigorous API validation testing including pressure and thermal reversals, high tensile (100,000 lbs), and compressive forces (300,000 lbs), confirming its ability to withstand 10,000 psi, 60-177C, and provide a gas-tight, high-load solution.

Project Results

The operational planning commenced when the customer allocated a well with sustained casing annulus pressure. After securing the well and conducting a Cement Bond Log (CBL) and caliper survey, the Viking Washover Assembly was run in the hole on the drill pipe to prepare the tubing stump, resulting in a suitable OD finish and external lead to accommodate the sealing system.

The Well Remediation System was deployed below a liner-hanger PBR system, engaging the tubing stump on the first attempt. After slacking off and taking an overpull to test the mechanical engagement, the annulus, and tubing were pressure tested to confirm full tubing integrity had been established.

Viking’s project implementation team worked closely with the client’s drilling and technical teams throughout the process, who were key to the operation’s success. The well was handed over to production nine days ahead of schedule, resolving the sustained casing annulus pressure with significantly reduced OPEX.

Well Data

| Location | Saudi Arabia |

| Well Type | Gas Producer |

| Completion Type | Cemented Monobore |

| Installations | Four |

| Casing Size | 9-5/8” 53.5# |

| Tubing Size | 4-1/2” 13.5# and 15.1# |

| Pressure | 10,000psi |

| Temperature | 60 – 177 °C |