Packers

Our API 11D1 (V0-V6 & V0-R to V6-R) certification, coupled with our in-house testing capability, allows us to supply packers rated to API 11D1 (ISO 14130) from levels V6 to V0.

We design and manufacture the full range of packers for production and injections wells for both oil and gas applications, covering pressure and temperature ranges up to 15,000 psi and 450 degrees Fahrenheit, respectively, in casing and tubing sizes ranging from 4-1/2” to 13-3/8” with a variety of specialized and standard material and elastomer types.

The simple, compact, and proven packer designs are set to be customized to suit specific applications.

The packer product range is complemented with a full range of accessories including: Anchor latches and back-off subs; Mill-out extensions and cross-overs; Adjustable unions and swivel subs; Muleshoe and wireline re-entry guides; Gas vent valves; Landing nipples and associated equipment.

Our global track record includes the supply and installation of

- Retrievable hydraulic and mechanical set packers for low to medium-pressure well conditions

- Permanent hydraulic and mechanical set packers for hostile and high pressure/temperature/flow well conditions

- Cut-to-release hydraulic set packers for high-pressure wells requiring intervention planning

- ESP packers with various penetrator and feedthrough types

- Control-line feedthrough hydraulic set packers for passage of hydraulic and electric control lines

- Velocity string packers for through tubing applications

- Sealbore packers for lower completion applications

- Dual string hydraulic set packers for dual zone production wells

- Packer accessories including mill-out extensions, anchor latches, seal assemblies

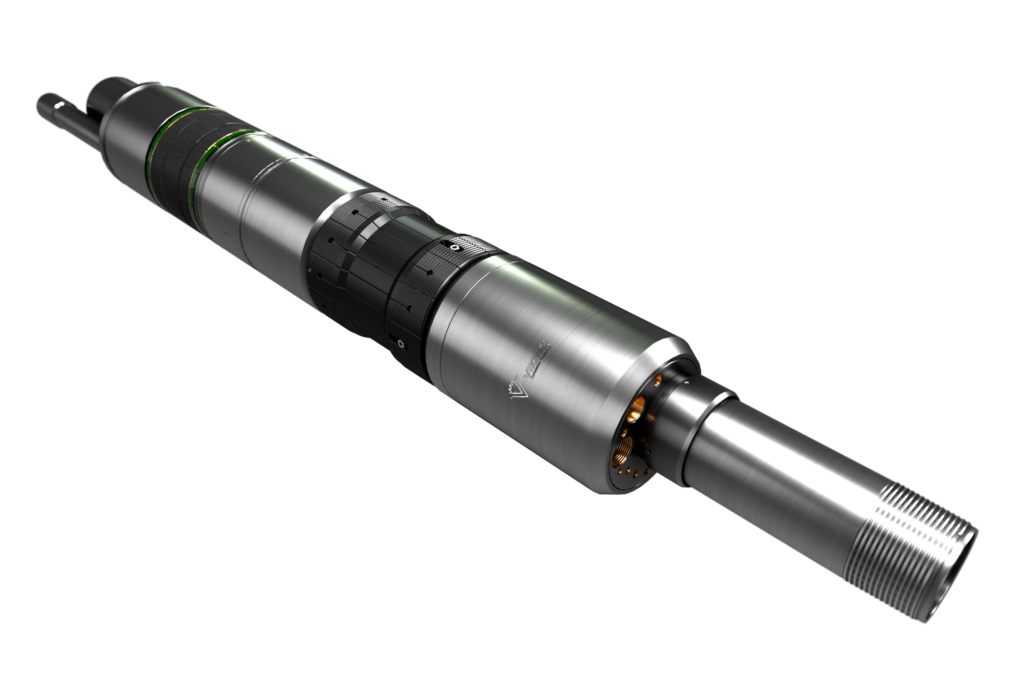

EZR ESP Packer

Viking Completion Technology’s EZR hydraulic set, retrievable ESP production packer provides high performance, easy deployment, and easy retrieval.

Utilizing a proven, gas tight, API-qualified, annular sealing system, it is capable of withstanding full-rated differential pressures, independent of the release force.

Deployed on tubing and retrieved through a straight-pull, the EZR is compact and configurable to suit a range of tubing sizes, material types, ESP penetrators, gas vent valves, and a variety of control line feedthrough requirements.

Suitable for vertical, deviated and horizontal wells, the EZR offers rugged deployment capability by virtue of torque-through features. High-grip, low-stress, 360° Barrel Slip provides suitability in aging wells.

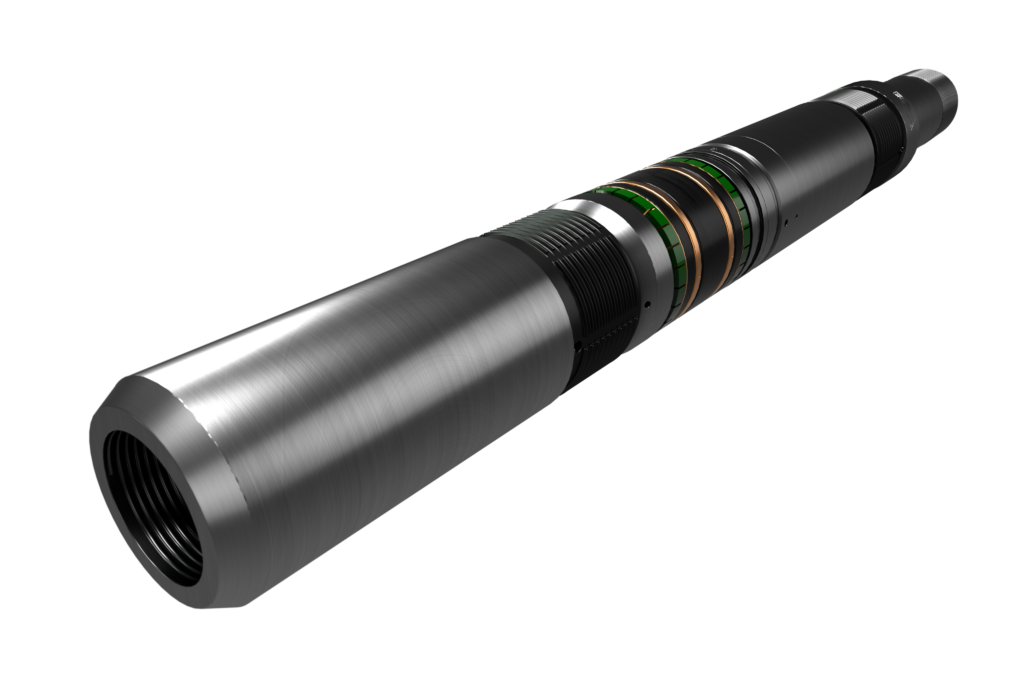

Permanent Hydraulic Set Packer

Viking's hydraulically set, permanent packer is designed to create a robust annular pressure barrier between the production tubing and casing. The packer is run into the well on the tubing string to the desired setting depth. Hydraulic pressure applied to the tubing string against a plug below the packer acts on the packer setting mechanism to set the slips and to expand the seal element to create a pressure seal against the casing wall. After the release of pressure, the internal locking mechanism holds the packer set. To remove the packer from the wellbore the tubing string is cut above the packer and a dedicated milling string is run to mill the packer and retrieve it from the well with minimal removal of material.

Dual Cut to Release Packer

Viking's Dual Cut to Release packer is run into the well on dual tubing strings, utilizing the optional integrated swivel to the desired setting depth.